Historically, cracked pipes were the source of nightmares for homeowners. Even now, the idea of digging up your garden and trenching through the mud, with weeks of messy work to fix a blocked sewer line or cracked pipe is terrifying. Thanks to epoxy pipe relining solutions, however, a broken pipe is no longer something to fear.

Instead of the traditional pipe repair or replacement methods that require direct access to the pipe, pipe relining services use key-hole, and CCTV systems to remotely repair your pipe from above the surface. This means no digging or destruction to your property.

If you are worried about what is involved in repairing your pipes because you can see the signs that you have a cracked pipe, this article will show you the reasons why so many homeowners are rejoicing at discovering the benefits of using epoxy resin pipe relining solutions.

Use the following links to jump directly to the section you’re most interested in:

- How epoxy resin is used to fix cracked pipes

- 5 reasons why people are choosing epoxy resin for cracked pipes

- Pipe relining vs replacement – Which is best for damaged pipes?

- The best long-term solution for fixing broken pipes

Ready to learn all about epoxy resin and how it can benefit your home or commercial pipes? Keep reading!

How epoxy resin is used to fix cracked pipes

Not sure how epoxy resin can be used to fix your pipes? If you’ve never heard of pipe relining with epoxy resin, it may sound too good to be true. Keep reading to learn the ins and outs of this advanced plumbing technology.

The 5 step process for epoxy resin

- First, we inspect your pipe to find the source of the issue. We run CCTV-like cameras inside your pipes to find exactly what’s wrong and to locate the concerning part of the plumbing. From the inside, we can see exactly how big the crack is, or if there is a blockage caused by tree roots or other debris.

- Next, we clean and prepare the drain using a high-speed water jet, again from within the pipe.

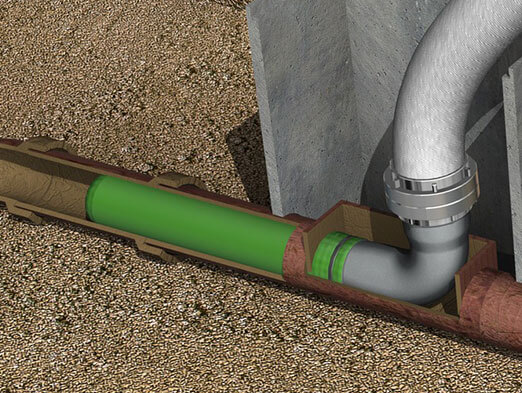

- Then, we insert an environmentally friendly textile liner and position it over the cracked section of the pipe.

- We cover that liner with a thick, epoxy resin that adheres it to the pipe wall. The epoxy resin works with the textile liner to create a new pipe within the wall of your old pipe.

- Finally, before we leave, we inspect the liner with our camera to ensure the repair is complete, and we leave you with a fully operational pipe and a 35-year guarantee.

5 reasons why people choose epoxy resin for cracked pipes

1. No Digging

The most obvious reason people choose to use epoxy resin pipe relining for cracked pipes is to avoid any need for digging.

This isn’t only a nice way to preserve your garden, but it can save your entire house. Imagine the troubles had by people in the past when the section of cracked pipe was discovered to be under or within the foundation of the house! The no dig, no mess promise is the number one reason people choose epoxy resin for cracked pipes.

2. Cost effective

By avoiding the messy work of digging up cracked pipes and sewer lines, the cost of pipe relining is significantly less than traditional pipe repair methods. On average, epoxy pipe lining comes in at 30-40% cheaper than the cost of traditional digging.

3. Lower risk

Another favourable benefit of not digging up pipes is that the entire pipe relining process is far lower risk. There’s no chance of digging up underground cables, accidents or any of the damage that can be caused by excavation, drilling, and digging.

In fact, a lot of epoxy pipe relining work can be done from a pre-existing access point. That means absolutely no cutting into pipes is involved throughout the entire process.

4. It works fast

In comparison to traditional pipe repair methods, pipe relining can have your pipes operational on the same day. There are no bounds to the benefits this gives homeowners, saving you the time, effort, and money of staying somewhere else while your plumbing is out of action.

5. More eco-friendly

The epoxy relining solution is a waste-free process. There is no waste produced during the repair of the pipes, and epoxy manufacturing does not produce carbon emissions either.

Epoxy relining allows you to keep your garden’s ecosystem uninterrupted, without adding any waste or destruction to the environment.

Pipe relining vs replacement – Which is best for damaged pipes?

To truly understand the answer to this question, we’ll look at the pros and cons of each of these solutions…

Pipe relining

Benefits of pipe relining

The benefits of pipe relining are clear and include:

- No digging

- Reduced cost

- Lower risk than traditional methods

- Fast working

- An eco-friendly option

- A 50-year lifespan with a 35-year guarantee

Cons of pipe relining

- Not right for every pipe issue.

- There are some circumstances where epoxy relining will not work. It can’t repair a completely collapsed pipe or be used on a back-pitched pipe where the pipe was installed incorrectly.

- Uses advanced technology

- While this is no concern for experts, there is a very exact process that must be followed correctly for the epoxy lining to work. Several things can go wrong if you aren’t properly equipped and trained in the process, making inexperienced technicians a high-risk liability.

Pipe replacement

Benefits of pipe replacement

- It can fix issues pipe relining can’t

- If a pipe has collapsed or been installed incorrectly, epoxy lining won’t be able to fix the pipe. In this instance, pipe replacement becomes the only option.

- It’s a good excuse to redo your garden.

- If you’ve been looking for an excuse to get a landscaper in and upgrade your garden, you’ve finally found it. Although this is a far more expensive way of doing it!

Cons of pipe replacement

- Higher cost

- Far more difficult and destructive

- Messy, noisy, and extremely disruptive

- Time-consuming

The best long-term solution for fixing broken pipes

Don’t mistake pipe relining as a band-aid solution. The epoxy resin creates a completely new pipe in your old pipe that is durable and watertight. Relined pipes are expected to last for 50 years, and we back them up with a 35-year guarantee.

The benefits speak for themselves. With no costly, time-consuming digging and a long lifespan, epoxy pipe relining is the best long-term solution for fixing broken pipes.

If you are facing the choice between digging up broken pipes or pipe relining, contact us today. We provide free site inspections and obligation-free quotes so you can feel confident and relaxed with our no dig, no mess pipe relining solutions. With over 20 years of industry experience saving thousands of homes across greater Sydney, we are here to help.

Back to Top