If you’ve been dealing with frequent drain blockages or unexpected leaks, you may have heard your plumber mention pipe relining as a lasting solution.

Unlike traditional pipe repairs that involve digging up your yard, pipe relining is a trenchless method that restores your pipes from the inside out, leaving them as strong as new. But here’s the thing: not all relining methods are the same.

So, what are the different types of pipe relining, and how do you know which one is the best for your situation? Let’s get into it.

Why Different Types of Relining Exist

All types of pipe relining techniques leave you with strong, seamless pipes within existing pipe systems, but different pipe conditions require different approaches. The best technique for your pipe relining project depends largely on the size of the pipe, bends and changes in diameter, the severity of damage and the location of access points.

For example, pipe relining can reduce the diameter of pipes, so some methods may not be as suitable as others for ensuring the flow is not restricted. Similarly, some methods are better for repairing longer sections of damaged pipe.

Different Types of Pipe Relining & Their Uses

Let’s look at the most common pipe relining materials and the methods that are used to rehabilitate ageing or damaged pipes.

The Most Common Method: Cured-In-Place Pipe (CIPP) Relining

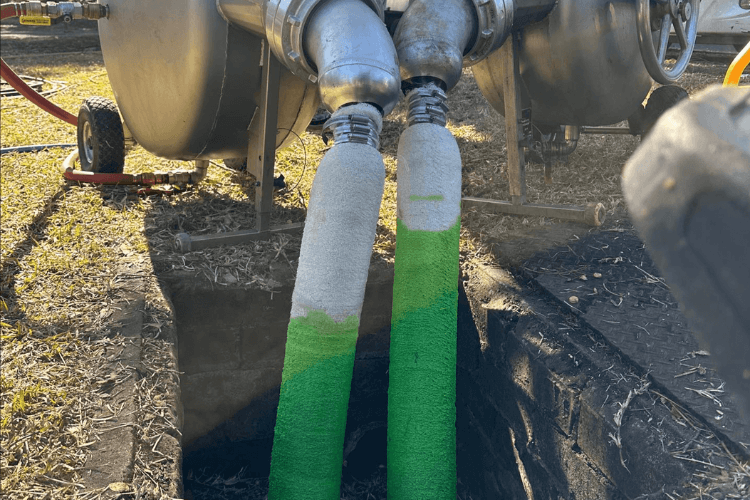

The most common trenchless pipe repair method, CIPP, involves inserting a textile liner that has been pre-saturated with epoxy resin into broken or damaged pipes. The liner is then cured in place.

Sometimes heat, in the form of steam or hot water, is used. However, UV light is also a popular method to harden the liner so that it becomes a new pipe within the existing pipe.

CIPP is highly effective because factory pre-impregnation ensures consistent quality, better adhesion and longer lifespan. It’s also faster because plumbers don’t have to handle or apply resin on site, and because it creates a seamless pipe, it eliminates the likelihood of weak points, so it’s an extremely long-lasting solution.

This method can be used on a wide range of pipe sizes and materials with minor to moderate damage, in residential, commercial and industrial settings.

What is Inversion Pipe Relining?

When using CIPP relining, a method called inversion uses a drum to turn the liner inside out and push it through the pipe using air or water pressure. The liner can only adhere to the pipe wall when it is inserted using constant, uniform pressure. One of the main benefits of inversion pipe relining is that it only requires a single access point, so it’s ideal for residential applications. The alternative to inversion for CIPP is pull-in-place relining, which we will talk about more below.

When Pull-In-Place (PIP) Relining Is Preferred

The pull-in-place relining process is very similar to CIPP, as it also uses a flexible, resin-coated liner to create a new pipe within the existing sewer pipe or drain. The main difference is that once the liner is inserted into the plumbing system, cables are used to pull it into the correct position. This allows for a more controlled placement, so it’s the preferred pipe relining process for larger pipes of longer lengths with more extensive damage, particularly on commercial projects.

For Smaller Pipe Relining Repairs: Brush Coating

Another method of pipe relining that is used for repairing damaged pipes of small diameters is called brush coating. This involves applying an internal pipe coating of epoxy resin by either spraying it on or using a spinning brush to apply it. This method is most often used for minor internal pipe repairs.

The resin is applied in multiple layers to seal cracks and stop leaks. However, it’s generally only suitable for small, localised repairs.

Alternative Trenchless Methods: Pipe Bursting vs Relining

While pipe bursting isn’t a form of relining, it’s another trenchless method for repairing pipe systems. Commonly used to replace existing underground sewer pipes, pipe bursting is akin to traditional pipe replacement, using smaller pits to remove sections of decayed, collapsed or broken pipes. (Although it requires some excavation, it’s still referred to as a ‘trenchless method’.) The process uses a tool called a bursting head to break up the existing pipe so that a new pipe can be pulled into place.

While relined pipes can reduce the diameter of existing pipes, pipe bursting is an ideal alternative when pipes of a larger diameter are required. For example, if you’ve renovated your home and added a second bathroom that requires a larger capacity pipe. However, it’s generally more expensive than relining pipes that are structurally sound and can be easily restored.

Which Pipe Relining Method Is Right for You?

Pipe rehabilitation by relining is a permanent, cost-effective solution for fixing cracked pipes or extending the lifespan of ageing pipe systems. However, it involves specialised equipment and expert know-how to ensure durable, long-lasting results.

When you have a pipe relining specialist assess your pipes, they will consider a range of factors to determine the best method of relining, including the pipe materials and their condition. They will use specialised tools to perform internal inspections and methods like jet cleaning or robotic cutting to clear obstructions in preparation for the relining process. Therefore, if you’re considering pipe relining to rehabilitate your pipes and stop plumbing problems for good, it’s best to have an expert assess which method is right for your situation.

The No-Dig Solution That Will Save You Time and Money

If you’re worried about root intrusion causing blockages in sewer lines or deteriorating pipes, flooding your home or backyard, pipe relining offers the ideal solution. It’s permanent, fast, cost-effective, and there’s no mess.

To have one of our experts assess your Sydney home for trenchless pipe relining, call The Relining Company on 0488 885 166 or visit our website to learn more about why our pipe relining systems are a superior solution.

FAQs

What are the methods of relining?

The three most common methods of pipe relining are cured-in-place, pull-in-place and brush coating.

What pipe materials can be relined?

Relining can be used on a wide range of pipe materials, including older clay pipes and cast iron pipes. It’s also suitable for concrete pipes and polyvinyl chloride (PVC).

What are the different types of pipe wrap?

Pipe wrap, used to repair cracked pipes, is usually made of fibreglass, rubber or foam. While it often involves using a resin-impregnated bandage to repair pipes, similar to pipe relining, it is only for localised issues and doesn’t last as long as relining.

How much should pipe relining cost?

The cost of pipe relining will depend on the pipe material and the extent of damage, among other factors. It’s always recommended to seek quotes from reputable pipe relining experts that break down costs specific to your home or business.

What are the different types of pipe braces?

Pipe braces, also known as pipe supports, are available in several different types, depending on their application. They range from rigid supports that restrict movement and spring supports that allow for thermal expansion, through to snubbers that absorb shock loads.

Back to Top